From Assembly to One-Shot Manufacturing: A New Paradigm for Aerospace Structures

- kaan deniz

- 8 hours ago

- 3 min read

Despite rapid technological progress, much of aerospace manufacturing still follows a 20th-century logic: separate processes, multiple assemblies, and hundreds of fasteners used to integrate complex structures. While this approach has ensured reliability and certifiability, it also introduces excess weight, structural inefficiencies, and significant manufacturing complexity.

But what if aerospace structures were no longer assembled piece by piece?

A shift toward hybrid manufacturing, where Additive Manufacturing (3D printing) and Automated Fibre Placement (AFP) operate in a single integrated process, could fundamentally redefine how we design and build next-generation aerospace systems.

Traditionally, aerospace components are manufactured individually and later joined through fastening or bonding. Each joint adds mass, inspection requirements, and potential failure points. More critically, assembly constraints often dictate design decisions, forcing engineers to segment structures based on manufacturability rather than optimal load paths. This results in redundant interfaces, stress concentrations, and lifecycle maintenance challenges.

Hybrid manufacturing offers a different pathway. Instead of discrete part production followed by assembly, a highly automated manufacturing cell could integrate continuous fibre thermoplastic placement with in-situ additive manufacturing of complex geometries, joints, and interfaces. In such a system, AFP would reinforce primary load paths with continuous fibres, while additive manufacturing would enable geometric complexity beyond the limits of fibre placement alone. Consolidation could occur during the build through controlled thermal processing.

The result is a unified, physics-driven workflow: structures that are printed, placed, consolidated, and optimised within a single continuous process.

This paradigm could enable the production of satellite trusses, fuselage sections, and even wing structures in a single build. Load-bearing regions would be reinforced along tailored load paths, while intricate interfaces and functional features would be additively manufactured in situ. The need for fasteners, secondary bonding, and multi-stage assembly could be significantly reduced or, in some cases, eliminated.

The structural implications are substantial. Fewer joints mean lower mass, improved fatigue performance, and enhanced structural continuity. More importantly, engineers would gain the freedom to design directly around structural load paths rather than manufacturing limitations. Thermoplastic composites are particularly well-suited for this vision due to their weldability, recyclability, and rapid processing characteristics, making them ideal for integrated and automated production environments.

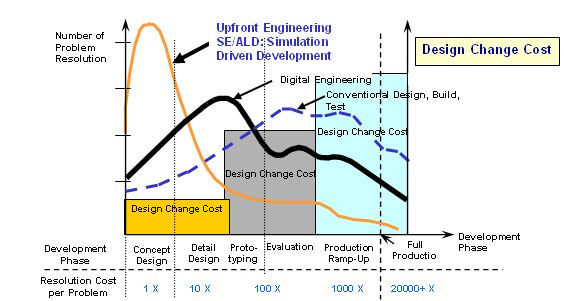

However, the primary bottleneck is not the capability of the machines. Advanced AFP systems, robotic additive manufacturing, and thermoplastic processing technologies are already evolving rapidly. The real challenge lies in accurately modelling the fully coupled thermal, mechanical, and crystallisation physics that govern hybrid thermoplastic processing.

During manufacturing, temperature evolution, material viscosity, consolidation pressure, and crystallisation kinetics interact simultaneously and directly influence void formation, bonding quality, and residual stresses. Without predictive multi-physics modelling and digital-twin-driven process control, achieving repeatable, certifiable one-shot manufacturing remains difficult.

Certification will also require a paradigm shift. Current aerospace standards are heavily based on component testing, joint validation, and assembly inspection. Highly integrated one-shot structures challenge these frameworks, raising key questions about inspection, certification, repair, and lifecycle performance of complex, joint-minimised architectures.

Looking ahead, the future of aerospace manufacturing may move from assembly-driven production to digitally integrated, hybrid workflows. By combining AFP and additive manufacturing within a single automated process, we can move toward lighter, more efficient, and structurally optimised systems tailored directly to physics and load paths.

The next generation of aerospace structures may not be assembled. They may be manufactured in one shot through hybrid, digital-twin-driven processes, first on Earth, and eventually, in space.

Comments